JLD – Film faced plywood – Description

| Face & Back | Smooth /Anti-Slip |

| Film | Black/Borwn/Red/Yellow/Green |

| Core | Finger Joint/Poplar/Hardwood/Eucalyptus/Pine/Birch |

| Glue | MR/Melamine/WBP/Phenolic |

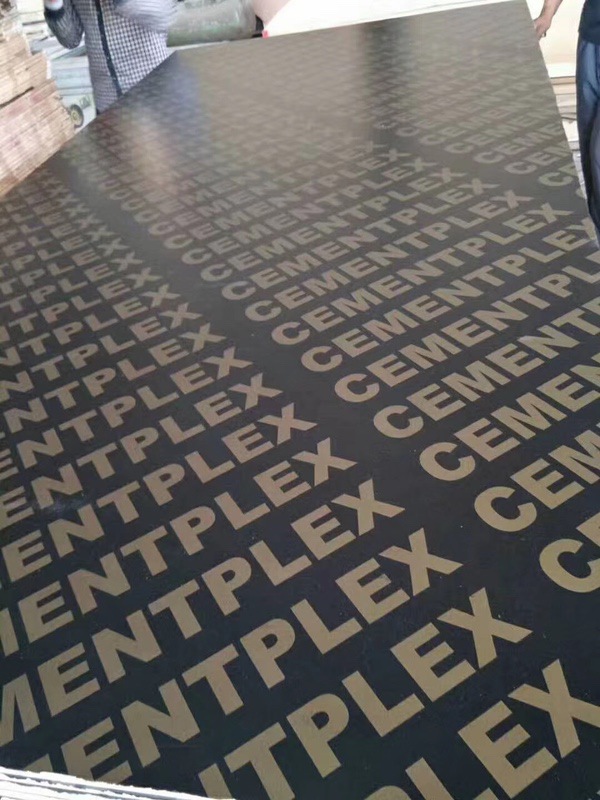

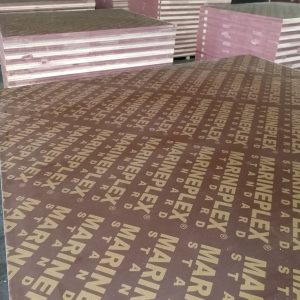

| Logo | According to Order( Customize your own logo) |

| Size | L:2440-6000MM W:1220-20000MM Thickness: 3-35MM |

JLD – Film faced plywood – Advantage

According to the types of face/back, film faced plywood can be divided into smooth film faced plywood and anti-slip film faced plywood.

Smooth Film faced plywood is waterproof marine plywood manufactured for concrete shuttering and formwork.

It is suitable for multiple uses, cheap, easy to clean and cut, and thus intensively used by formwork companies.

Film faced plywood is manufactured with quality veneers with WBP glue that can withstand harsh weather and rain.

Both sides of the plywood are coated with an opaque phenolic film overlay and the four edges are sealed with waterproof paint.

The film can be custom printed.

To provide you with a variety of choices, quality, and economic win-win.

Anti-slip film faced plywood is usually used as flooring materials for vehicles, trucks, and platforms.

During the coating process, a slip-resistant pattern ( Hexagon/ Wire-mesh/square grid ) is hot pressed onto the film surface.

The edges will be coated with waterproof paint.

Anti-slip patterns maintain skid resistance in all climatic conditions, making anti-slip plywood an ideal flooring material.

JLD – Film faced plywood – Upscale & Premium

| N/M | Item | Units | Standard | Result | Conclusion |

| 1 | Thickness | mm | 15mm ±0.5 | 15.1 | Qualified |

| 2 | Density | Kg/M3 | 500-600 | 690 | Qualified |

| 3 | Moisture Content | % | 5-14 | 7.5 | Qualified |

| 4 | Bonding Strength | Mpa | ≧0.70 | 1.56 | Qualified |

| 5 | Longitudinal Static Bending intensity | Mpa | ≧40 | 78.5 | Qualified |

| 6 | Transverse Static Bending intensity | Mpa | ≧30 | 70.4 | Qualified |

| 7 | Longitudinal Modulus of elastic | Mpa | ≧5000 | 8938 | Qualified |

| 8 | Transverse Modulus of elastic | Mpa | ≧4000 | 7570 | Qualified |

JLD – Film faced plywood – Midscale & Standard

| N/M | Item | Units | Standard | Result | Conclusion |

| 1 | Thickness | mm | 15mm ±0.5 | 15.1 | Qualified |

| 2 | Density | Kg/M3 | 500-600 | 580 | Qualified |

| 3 | Moisture Content | % | 5-14 | 7.5 | Qualified |

| 4 | Bonding Strength | Mpa | ≧0.70 | 1.50 | Qualified |

| 5 | Longitudinal Static Bending intensity | Mpa | ≧40 | 60 | Qualified |

| 6 | Transverse Static Bending intensity | Mpa | ≧30 | 45.50 | Qualified |

| 7 | Longitudinal Modulus of elastic | Mpa | ≧5000 | 6990 | Qualified |

| 8 | Transverse Modulus of elastic | Mpa | ≧4000 | 6100 | Qualified |

JLD – Film faced plywood – Economical & Common

| N/M | Item | Units | Standard | Result | Conclusion |

| 1 | Thickness | mm | 15mm ±0.5 | 15.1 | Qualified |

| 2 | Density | Kg/M3 | 500-600 | 540 | Qualified |

| 3 | Moisture Content | % | 5-14 | 8 | Qualified |

| 4 | Bonding Strength | Mpa | ≧0.70 | 1.10 | Qualified |

| 5 | Longitudinal Static Bending intensity | Mpa | ≧40 | 54.00 | Qualified |

| 6 | Transverse Static Bending intensity | Mpa | ≧30 | 42.00 | Qualified |

| 7 | Longitudinal Modulus of elastic | Mpa | ≧5000 | 5210 | Qualified |

| 8 | Transverse Modulus of elastic | Mpa | ≧4000 | 4600 | Qualified |

JLD – Film faced plywood – Packing And Loading